SYNCHRONOUS MOTORS

Synchronous motors are

synchronous machines used to convert electrical

power to mechanical

power. This subject explores the

basic operation of

synchronous motors and relates their behavior to that of synchronous generators.

If the

stator magnetic fields in a synchronous motor rotate

at a low enough speed,

there will be

no problem for the rotor to accelerate and to lock in with the stator

magnetic field.

The speed of the stator magnetic fields can then be increased to

operating

speed by gradually increasing fe up to its normal

50- or 6O-Hz value.

This approach

to starting synchronous motors makes a lot of sense, but it

does have

one big problem: Where does the variable electrical frequency

come

recently any variable-frequency

voltage source had to come from a dedicated

generator. Such

a situation was obviously impractical except

for very unusual

circumstances.

Today, things

are different. With the development

of such modern solid-state variable frequency drive packages, it is perfectly possible to continuously control the electrical frequency applied to the motor all the way from a fraction of a hertz up to and above full rated frequency. If such a variable-frequency drive unit is included in a motor-control

circuit to achieve speed control, then starting the synchronous motor

is very

easy- simply adjust the frequency to a very low value for starting, and then

raise it up to the desired operating frequency for normal running.

Motor

Starting with an External Prime Mover

The second

approach to starting a synchronous motor is to attach an external starting

motor

to it and bring the synchronous machine up to full speed with

the external

motor.

then the synchronous machine can be paralleled with its power

system

as a generator,

and the starting motor can be detached from the shaft

of the

machine.

Once paralleling is

completed, the synchronous motor can

be loaded

down in an ordinary fashion.

This whole

procedure is not as preposterous as it sounds,

since many synchronous

motors are

parts of motor-generator sets, and the synchronous machine

in the motor-generat

or set may be started with the other machine serving as the

starting motor.

Also, the starting motor only needs to overcome the inertia of the

synchronous machine without

a load- no load is attached until the motor is paralleled to the

power system. Since only the motor's inertia must be overcome, the

starting motor can

have a much smaller rating than the synchronous motor it

starts.

Since most

large synchronous motors have brushless excitation systems

mounted

on their shafts, it is often possible to use these exciters as starting motors.

For

many medium-size to large synchronous motors,

an external starting

motor

or starting by using the exciter may be the only possible solution, because

needed to use the amortisseur winding approach described next.

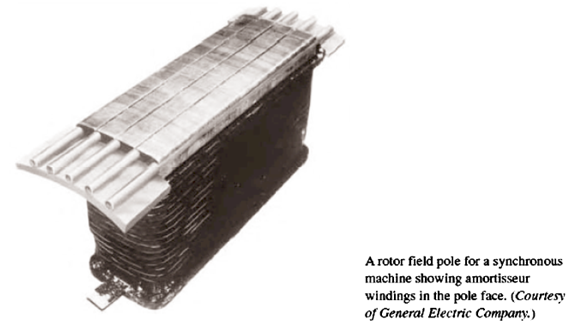

Motor Starting by Using Amortisseur Windings

By far

the most popular way to start

a synchronous motor is to employ amortisseur

or damper windings. Amortisseur

windings are special bars laid into notches

carved

in the face of a synchronous motor's rotor and then shorted out on each end

by a large shorting ring.

No comments:

Post a Comment